How To Identify The Correct Coolant - Auto Service World

Not all that long ago, no matter which brand of antifreeze you chose, it was green. Today, with different types of antifreeze technology in a rainbow of colours, confusion abounds among automotive people and consumers alike as to what colour antifreeze is best. The easy part is that most antifreeze manufacturers still make coolant with ethylene glycol (EG), while some use less-toxic propylene glycol (PG).“Coolants in automotive light-duty applications are dyed many different colours; the colour of any automaker’s particular coolant does not tell the technician what the formula is. It doesn’t even signify what manufacturer the coolant was OE on. As an example, there are at least three different shades of green coolant from three different manufacturers, [and] none are the same formula,” explains Prestone technical training director Jay Buckley.Evolving AntifreezeEngine coolants perform several functions in addition to providing freeze and boil protection. Coolants must also contain additives that inhibit corrosion and scale formation in the engine and radiator. There are very many different types of corrosion inhibitor compounds in the market that are used in the formulation of engine coolants. Many of these are selected specifically for the purpose of inhibition of certain types of metal surfaces found in engine systems. Many modern engines use a variety of metals – from lightweight aluminum and aluminum alloys through to heavy-duty mild steel and heavier alloys. Each of these metal surfaces, and coolant design systems, present different corrosion inhibition problems that are addressed by different inhibitor compounds.Generally, coolant corrosion inhibitors can be categorized into three distinct types:1. Conventional inorganic corrosion inhibitor compounds (traditional coolants).2. Extended-life organic-acid inhibitor compounds (OAT coolants).3. Combinations of OAT and traditional inhibitors (hybrid or HOAT coolants).Inorganic acid technology (IAT) is the chemical basis for the traditional green antifreeze. IAT contains either EG or PG, and is usually fortified with silicate or phosphate additives to make it compatible with metal cooling system components.Conventional inorganic (traditional) inhibitors have been known in the marketplace for over 60 years, and were first known to exhibit corrosion prevention features early in the previous century. These compounds are soluble inorganic molecules, which react (passivate) with the metal surfaces to produce an impervious physical layer that prevents any further corrosion reactions from taking place. These compounds are therefore very effective at producing a barrier against corrosion. They are typically readily available and relatively cost-effective.Such types of compounds include a variety of elements: silicates, nitrites, nitrates, molybdates, phosphates and borates. In the past, amines were also used, but these have since become unfavourable due to the formation of carcinogenic nitrosamines.The disadvantage of the traditional inhibitor type is that over time, these impervious barriers can break away from the metal surface, exposing fresh metal underneath to further corrosion, and also creating insoluble particles in the bulk fluid that can be further abrasive. Therefore, such coolants have limited life, generally in the order of 50,000 km maximum.The life of a traditional coolant can sometimes be boosted by the incorporation of SCAs (supplemental coolant additives), which act as boosters, with super-concentrated mixtures of the same traditional inorganic inhibitors.Organic Acid Technology (OAT) is a long-life coolant (LLC) / extended-life coolant (ELC), widely used in Europe before its introduction in North America. OAT is usually EG. The generally recommended replacement interval is five years or 225,000 kilometres. Vehicle owners should always refer to the vehicle manufacturer’s recommendations for coolant type.Since the late 1980s, considerable research has been undertaken on the development of genuine long-life coolants, which form a molecular layer or barrier. Unlike the physical barrier formed in the use of traditional inorganic inhibitors, these molecular layers are formed by the OAT molecules lining up on the metal surface, due to very finely tuned behaviour in their polarity. These molecular layers exhibit the same effect, preventing the metal surfaces from coming into contact with the corrosive base fluid. When the molecular layer is periodically interrupted (say, from particles of debris in the cooling system), it automatically reforms from other temporarily unattached OAT molecules in the cooling system. In this way, the layer continually reforms and repairs itself, and therefore the fluid’s life is considerably extended.OAT molecules are typically weak buffered carboxylic acids with long (C8-C10) carbon chain length “tails” and polar heads. A wide number of different OAT molecules are now used – some more widely than others, some with more unique preferences than others. Different OAT molecules exhibit different corrosion behaviour in different metal surfaces, and therefore many modern OEMs can be quite specific about the types of OAT molecules that the formulation must (or must not) contain.Hybrid organic acid technology (HOAT) combines IAT and OAT with nitrites. Antifreeze manufacturers often refer to it as “global,” indicating on the bottle that it meets or exceeds the specification G-05 for most vehicles newer than 2002 and G-11 or G-12 for Volkswagen and Audi.Valvoline’s Zerex G-05 antifreeze is a hybrid organic acid technology (HOAT) chemistry that combines the best of conventional and organic acid-based chemistry to provide protection against rust and corrosion. Zerex uses ethylene glycol for freeze and boilover protection, and a hybrid organic acid corrosion inhibitor package to protect engines from liner pitting and corrosion, and protects all system metals including aluminum.Due to the rapid development of different engine componentry and metallurgy since the 1990s, much effort has gone into the development of enhanced OAT coolants. Many engine types have indeed been shown to exhibit improved corrosion resistance over a longer life, with a combination of both OAT molecules (providing an extended life molecular barrier) with some specific inorganic compounds that enhance very specific performance features of the coolants.This is particularly the case in some heavy-duty on- and off-road engine types, which may specify the use of OAT type coolants fortified with nitrites and/or nitrites and molybdates, but also some passenger-car engine types that specify OAT inhibitors fortified with silicates and others, or phosphates.Such engine coolants are generally referred to as “hybrids,” and typically offer similar life and performance to OAT-type coolants, specifically tailored to certain engine types.The generally recommended replacement interval is five years or 225,000 kilometres. Always recommend your customers check their vehicle manufacturer’s recommendations for their car or truck.Can You Mix Antifreeze Technologies?The one universal coolant that all agree on is water. For best performance, water needs a little help. What happens when coolants are mixed?A lot of the confusion about mixing coolants stems from early work with carboxyl coolants. In an American Society of Testing and Materials (ASTM) test, mixing IAT and OAT coolants resulted in more corrosion than either antifreeze alone. Subsequent tests revealed a testing error: the corrosive environment occurred because the coolant was too diluted.It is best to recommend to your customers to use the same type of coolant originally used by referring to the vehicle manufacturer’s recommendations.

???what is our engine coolant???: what is our coolant?? can i add water to it? can i use universal? http://bit.ly/mL20dv

— DodgeForum Sun May 01 20:40:17 +0000 2011

-

Latest

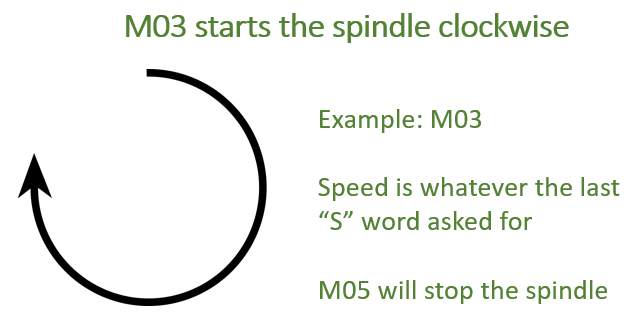

G-Code Cheat Sheet + MDI: Your CNC Secret Weapon

G-Code Cheat Sheet + MDI: Your CNC Secret WeaponG-Code Cheat Sheet for MDI CommandsYou’ve got the basic picture of how MDI will work, so now it’s time to get into the exact g-codes you’ll want to use and get them together on a Cheat Sheet for you.M...

-

Next

What's the Difference Between Antifreeze and Coolant?

What's the Difference Between Antifreeze and Coolant?If you own a car or a truck, even if you do not do much of your own vehicle maintenance, you have probably at least heard of antifreeze and coolant. It sounds as if they serve very similar purposes in...

Popular Articles

- Why Do Smartphones Become Anchors in Daily Decision Flow?

- Why Does Refresh Rate Matter Beyond Smooth Scrolling?

- What Makes a Smartphone Feel “Comfortable” to Use Daily?

- The 5-minute Phone Declutter: Organize Your Apps and Mind

- AI Features Changing the Smartphone Experience

- Must-Have Smartphone Features This Year